Optical module and control software for the laser-based production of tribological multi-layer systems

Tribological layers effectively protect heavily stressed components against wear and reduce friction. These layers are normally produced in kiln processes. The substrate is exposed to an increased thermal load, but the process results in a mixing of the individual layers. In the scope of the joint project “Additive Laser Processes for Producing Tribological Multi-Functional Layers for Energy-Efficient Systems”, or ATSM, which is funded by the Federal Ministry of Education and Research (BMBF), the Fraunhofer ILT and the Eloxalwerk Ludwigsburg Helmut Zerrer GmbH (ELB) joined forces with Pulsar Photonics to develop a new and innovative method for the laser-based production of tribological multi-layer systems on lightweight components.

David Pallasch, the lead ATSM project manager at Pulsar Photonics, was available for a brief interview at the conclusion of the research project.

Mr. Pallasch, after almost two and a half years of research, the “ATSM” research project is nearing completion. What specifically was the objective and who participated?

The goal of the research project was to develop a polymer coating system consisting of a corrosion protection layer, a tribological layer and a sacrificial layer. The three layers each consist of the PEEK high-performance polymer, with the different layers enhanced with various additives. These additives alter the properties of the polymer according to the corresponding function of the layer.

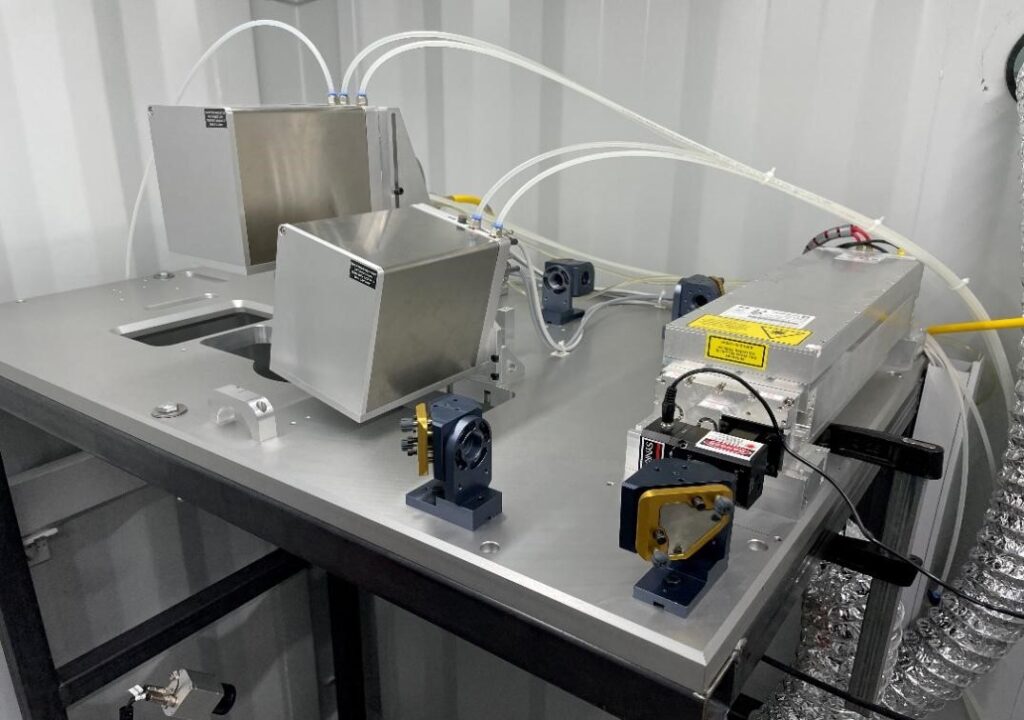

The ILT and ELB have focused their efforts on developing the individual layers and the composition and concentration of the additives, while we have developed an optical module for the laser melting process and suitable control software. The excellent communication and good atmosphere throughout the project, despite the complicated circumstances and travel restrictions during the second half of the project, led to a very satisfactory result for all participants.

Can you briefly describe the process of the laser-based method?

The PEEK powder is first applied by spraying or pressing, and this is then melted on precisely by means of laser radiation. Several melting or preheating runs over the part can be freely configured. The part is supplied, aligned and moved under the processing head by a robot.

Looking back, what was the biggest challenge for your team during this research project?

The integration of two scanning heads and two lasers for the combined heating and melting process proved to be a challenging task not only for our software department but also for our design engineers and production department. Luckily, for the planning and construction of the optomechanics, we were able to rely on our many years of experience in specialized mechanical engineering and an extensive kit of self-developed system technology components.

Process flexibility was a priority for the implementation of the software, which is why we have fundamentally revised and revamped our previously only rudimentary process editor. This now enables us to easily set up and configure not only complex processes for microstructuring, but also other projects like ATSM or other extensive laser processes. With the new editor and process modules specially developed for ATSM, we were able to successfully implement the process with process steps running partially in parallel, laser control in the process and communication with the robot via I/O modules.

About the interviewee:

David Pallasch received his M. Sc. in Optical Technologies / Electrical Engineering from the Cologne University of Applied Sciences. For the past four years, he has worked as a software developer and project engineer at Pulsar Photonics.