How are requirements for a laser machine written?

Product Requirements Document for a laser machine: a comprehensive guide on the most important contents

Louisa Draack | 6th of February 2024 ᛫ 15 Min.

The efficient planning and execution of machine purchasing projects in the field of laser technology begin with a clear and detailed set of requirements. Customers often face the challenge of precisely expressing their specific requirements while not yet having a clear idea what the laser process will look like and which machine technology is required. It is possible that there are already very concrete ideas regarding the implementation and application but the specific process sequence and laser technologies are not determined yet.

In this case, the creation of a product requirements document (PRD), which details the application, the desired sequence and the target, is helpful. With this article we aim to provide a comprehensive guide on how to put together such a document which clearly lists what it is you require and which provides sufficient scope for the supplier to find the best solution for your requirements. We will touch on the following aspects:

- What is a product requirements document and what is it used for?

- Difference to functional specifications

- When do such documents have to be created?

- What belongs in a requirements document?

- Our most important advice

- Template for a product requirement document

What is a Product requirements document and what is it used for?

According to DIN 69901-5, the definition of a product requirements document (German: “Lastenheft”) is defined as follows:

„Vom Auftraggeber festgelegte Gesamtheit der Forderungen an die Lieferung und Leistung eines Auftragnehmers innerhalb eines Auftrages“

Translation: “The totality of requirements set by the customer for the delivery and services provided by the contractor within an order”.

Just like the initial feasability tests in the laser application center, the PRD serves to establish early on, which requirements are present and how they can be fulfilled.

Important functions of the PRD therefore are to indicate technical details, targets, the desired timeline and potentially the financial expectations.

Which differences exist between PRD and Technical Specifications?

With the term “technical specifications” we are referring to the German term of “Pflichtenheft”. While the PRD is written by the customer or client, the technical specifications are the contractors or manufacturers answer to these requirements. The contents of the specifications therefore describe, how the desired requirements can be realized and clearly outlines, which points cannot be fulfilled for example due to physical limitations of laser technology.

When does a Product requirements document (for a laser machine project) need to be created?

Ideally, the PRD should be created in the initial phase of a project. The success and lead time of a laser machine project are heavily dependent on how early and accurately the requirements are described. Ideally, the first version should be created before contacting potential suppliers. A requirements analysis should be done in advance in order to determine which wishes and prerequisites are posed to the laser macine by the various stakeholders.

After discussing the desired application with the various laser machine manufacturers, the product requirements document can be adjusted and further specified based on their experience.

It is advantageous for the PRD to be finalized shortly before the assignment because its contents are subject to the negotiations and subsequently form a core component of the contract. Should changes later be desired which carry an impact on pricing, this often entails a follow-up order and an extension of the delivery timeline.

What should the Product requirements document (for a laser machine project) contain?

As always, “as little as possible, as much as necessary” applies. In this context it is important that contents are communicated openly and as accurately as possible to avoid any open questions or misunderstandings on the recipient’s side. For this, the contractor needs to know which targets and results the customer is looking to achieve and which purpose the laser machine is to be purchased. Nonetheless, there has to be sufficient scope for the supplier to implement solutions based on their point of view and prior experience and if possible founded on their existing machine portfolio.

Project overview and definition of targets for a laser machine project

In the introduction, the customer explains, which purpose the project is to serve, what motivation and targets are present and in which context the project is planned.

Requirements for the laser process are briefly summarized to provide an overview for the potential contractor so they may determine, whether or not their existing machine lineup matches the requirements and if the inquiry is relevant to them.

This is also an opportunity to communicate the desired delivery time so the supplier can check, whether or not it is achievable based on their projected capacity utilization.

Project participants and their contact information should also be mentioned at this stage.

In addition, a display of the change history can serve to make the document’s versions traceable.

1. Description of the products to be machined

This chapter will go into greater detail concerning the planned application. It is important to closely and accurately describe the product to be machined and the planned application. Important information for the laser machine manufacturer includes:

- Number of planned products

- Dimensions of the workpieces (width x depth x height) and their shape

- Detailed description of the material with category and number

- Material thickness

- Coatings, platings or other surface treatments

- Machining task (drilling, welding, soldering, cutting etc.)

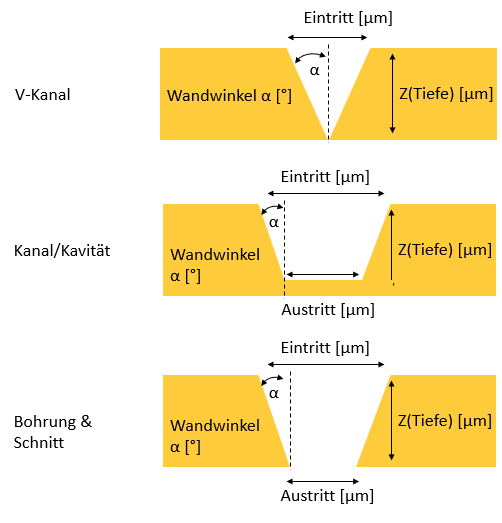

- Detailed description of the application e.g. by entry and exit diameter, borehole pattern, desired surface finish, machining depth

- Definition of the exact surface at which the machining is to be done

- Required accuracy of the machining

- Reference to technical drawings which are either directly introduced or added as an appendix

Description of the process sequence

Besides the product itself, the process sequence for the machine is also relevant to the first chapter. Most laser machines are manually loaded in their base configuration. Some manufacturers such as Pulsar Photonics provide the possibility of implementing an automated loading and unloading or a robot-based parts handling system within the laser machining enclosure. The customer’s process chain influences how these can be implemented.

Through a description of the machine’s sequence the supplier can understand, which orientation the workpiece has inside the machine, in which position it leaves the machine and if auxiliary components such as trays are available for the transport of the components. Additionally, the supplier learns whether the products are created in lots or as singles.

Detailed description of interfaces and requirements for software and hardware

Interfaces of the machine for the connection to a production data acquisition system or other databases in the customer’s environment should also be mentioned at this stage. This makes sure the contractor has the possibility to design such interfaces and potentially required sensors accordingly.

Many enterprises have precise requirements for the software. As these are highly relevant to the development of the machine’s software, it is essential for the interfaces to be specified in the requirements document. Should internal documents already exist for this purpose, they may be mentioned in the applicable documents and added as an appendix to the PRD. Required user interfaces are also to be mentioned in this section.

Frequently the rules apply not just to the software but also to specific hardware componentry or manufacturers thereof. The correspondent information is also relevant for the machine manufacturer in order to verify if and at what cost such provisions are realizable.

There are other factors which can also make specific components necessary. For example, previous testing with other laser manufacturers may have shown that a specific laser model is suitable. The precise designation of this laser source should in this case also be mentioned in the PRD. Further relevant requirements are the planned duration of use, the machine availability and the required cycle time.

In addition to the technically relevant information concerning the project, the planned project plan is decisive for the feasability of a project. This plan should include not only the desired date of delivery but also important milestones such as the date of order, the desired date of the FAT at the contractor’s production site as well as the SAT at the customer’s site where the machine is to be utilized.

2. Boundaries of the project scope

A clear demarcation of the project’s scope within the product requirements document is important so that the potential contractor does not offer componentry which lies outside of his area of responsibility.

Potential boundaries could be defined as follows:

- Is there a water-cooling solution on site which corresponds to the cooling specifications or is an auxiliary cooler, provided by the contractor, necessary?

- Is there an extraction system on-site which is able to remove the particles created in the laser process, or should a suitable unit for filtering and extraction be provided by the contractor?

- Which party shall provide the workholding chuck required for the laser process?

- If automatic loading and unloading is to be utilized, who shall implement the corresponding hardware?

3. Description of the machine site and environmental conditions

The environmental conditions at the site must be described in detail for the construction of the laser machine. Important information includes:

- Installation location including exact address and clean room qualification if applicable

- Existing plant or workshop layout including the maximum external dimensions, the maximum weight and available connections and hookups for the machines such as pneumatic supply, electrical connections, cooling water connections or extraction connections

- Maximum dimensions for the transportation of the laser machine to its final site

- Orientation of the machines in case of catenation

- Environmental temperature

- Relative humidity

4. Criteria for machine and unit approval

This chapter should contain a comprehensive list of factors which are relevant for the approval of the laser machine. The following is a non-exhaustive list of examples:

- Machine capability

- Machine availability

- Process capability (measurement e.g. by surface roughness, borehole diameter, precision)

- Other quality criteria (e.g. no marks on the workpiece left by handling components)

- Documentation requirements

- Safety requirements

- Ergonomic requirements

- Energy efficiency

- Training of personnel

5. Important documents for the laser machine project in addition to the PRD

Even though the product requirements document already contains many factors, there often are additional documents which are relevant to the realization of the project. These must be listed in the PRD with their title and date of publication in order to be considered for the project. The following documents may be relevant:

- Purchasing conditions

- Technical drawings of the workpiece

- Specifications for manufacturers, components, coloration

- Specification of the machine data acquisition system interface

- Layout plan

- Acceptance protocol

6. Miscellaneous

This chapter serves to list other important points which go beyond the description previously outlined. This could for example contain the following mercantile contents:

- Duration of warranty

- Terms of payment

- Bank guaranty

- Requirements for documentation

- Training of users

From our experience with projects here at Pulsar, we know that…

- a timely start before the project kick-off is helpful in order not to end up pressed for time and avoid missing important points

- help from the specialist deparments facilitates accurately describing the specialist fields (e.g. electrical, software) and to take into account all aspects which are difficult to assess as a non-specialist

- the legal and company internal requirements must not be forgotten

- attention should be paid to a precise but simple description of the application and the desired scope

- a robust version management helps to ensure both parties are referencing the same contents

Creating a product requirements document for your laser machine: what you shouldn’t forget

A project requirements document (PRD) for a laser machine project serves as the foundation for a successfull collaboration between client and contractor by defining clear and precise requirements. The consideration of all relevant technical, temporal and commercial aspects in the PRD ensures that both parties are operating on a shared basis of understanding. In this regard it is important to strike a balance between a detailed description and sufficient flexibility for the supplier to enable innovative and tailor-made solutions. Finally, a well-designed PRD is not only conducive to an optimization of the project duration and costs but also ensures that the end result fully meets the customer’s expectations. Hence, the creation of this document should be considered an investment into the quality and efficiency of the entire project. By following the recommendations given in this article, it is possible to ensure that the PRD serves as a powerful tool for the achievement of the project’s success.

The points which were not mentioned in this context can not be incorporated into the supplier’s offer and may lead to additional costs and a delay of the delivery.

More on the Author:

Louisa Draack, m. Sc.

Louisa Draack is responsible for the technical sales of laser micromachining units at Pulsar Photonics. She has a master’s degree in Industral Engineering from the FH Aachen and at the time of writing nearly six years of work experience in the area of laser machining with short and ultrashort pulse lasers.

translated by Joël Hafner