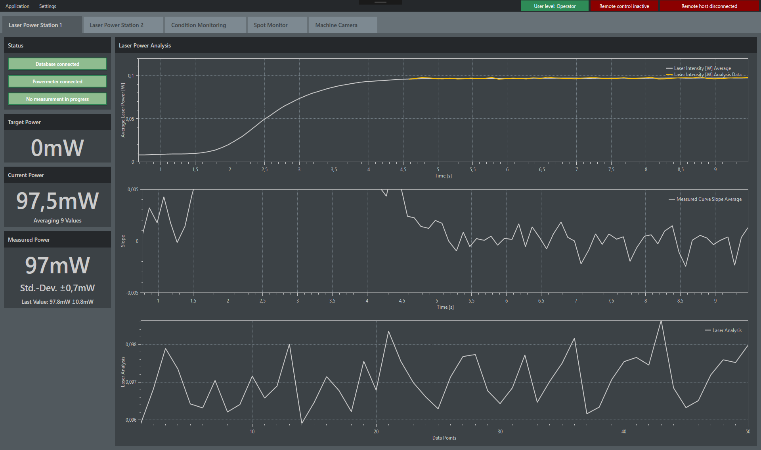

Machine control software

Photonic Elements

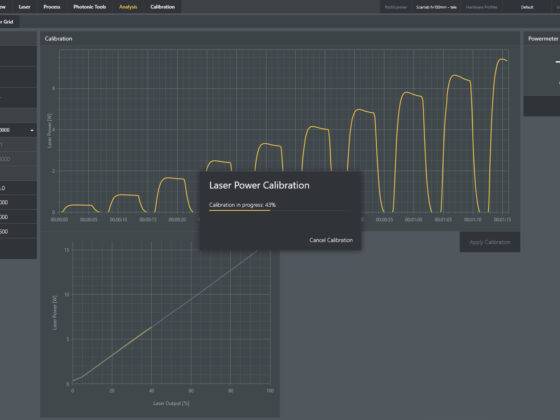

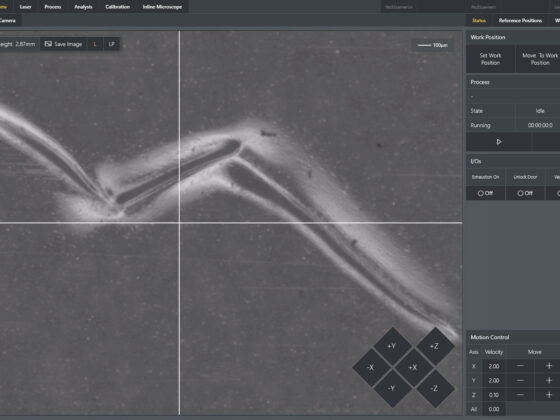

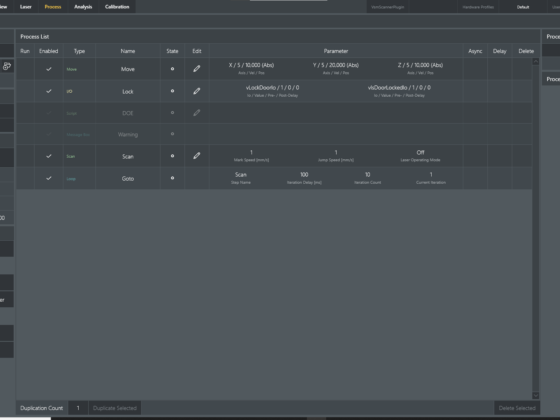

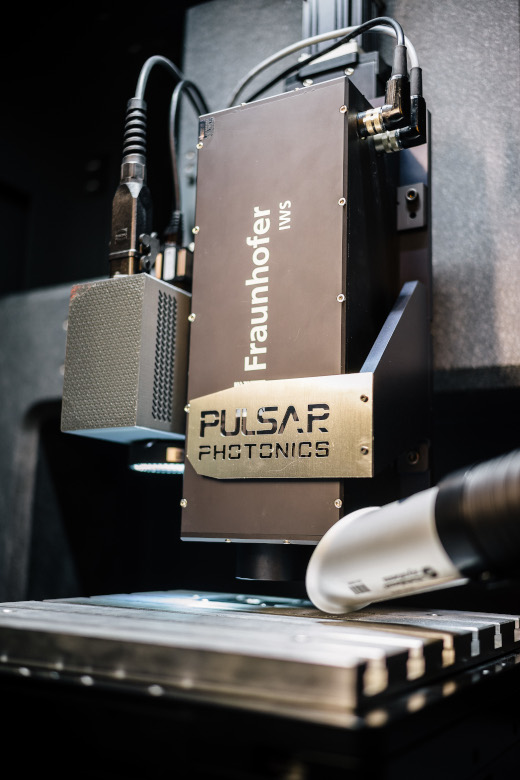

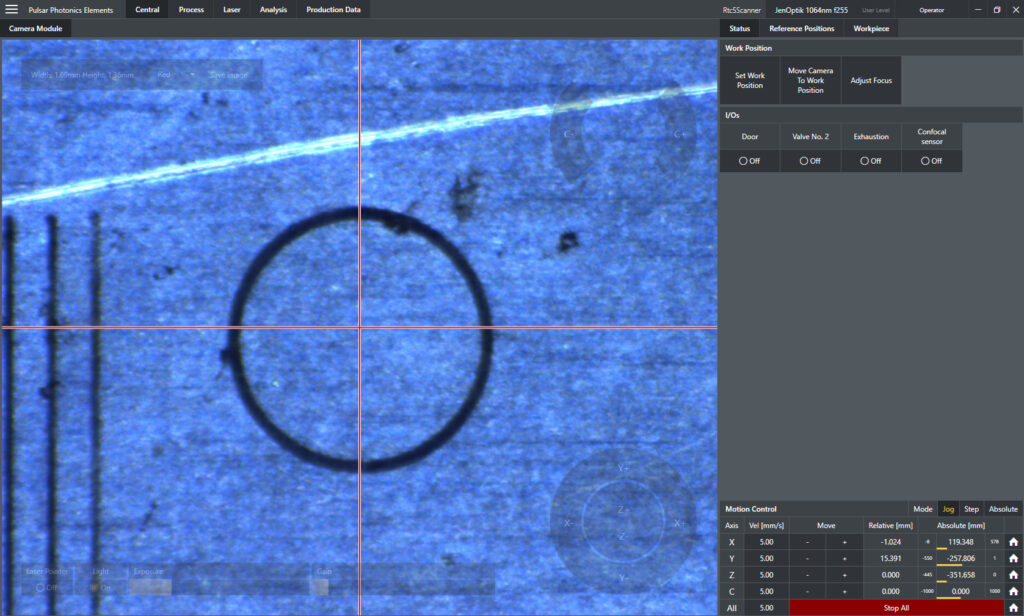

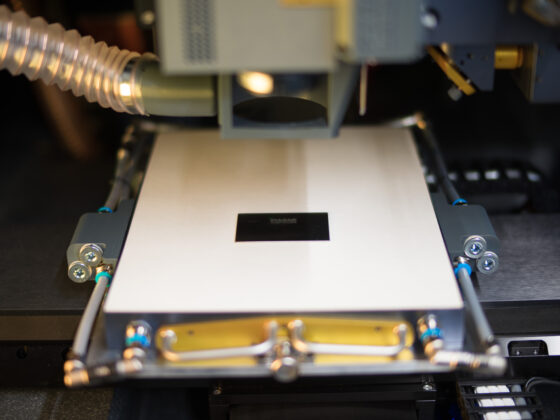

Photonic Elements is that Control and operating software for laser micro-processing . The laser software integrates the control of the individual machine components, the monitoring of safety-relevant functions and offers the user a context-related interface for tasks such as setting up the laser machine or executing process-related machining strategies. In addition to the control of short-pulse and ultra-short-pulse lasers, machine axes and galvanometer scanners, the status of the machine peripherals can be queried, I / O systems switched or technology modules integrated.

The parameters of the integrated components can be managed extensively within the system settings. Machining programs are either imported via the CAD-CAM software Photonics Vectors or generated directly. The software enables component measurement and process preparation, as well as a subsequent evaluation of the process results. Various process routines simplify and automate work on the machine and reduce the complexity of the processes.

The individual components of the machine can be monitored and readjusted if necessary via the integrated sensors; additional topography measurement technology enables the evaluation of the process results directly in the machine. By means of operating data acquisition, the machine usage can then be analyzed.

Clear and easy to use interface

Job editor with scripting to create process flows

Integrated CAD module

Measurement functions and data visualization

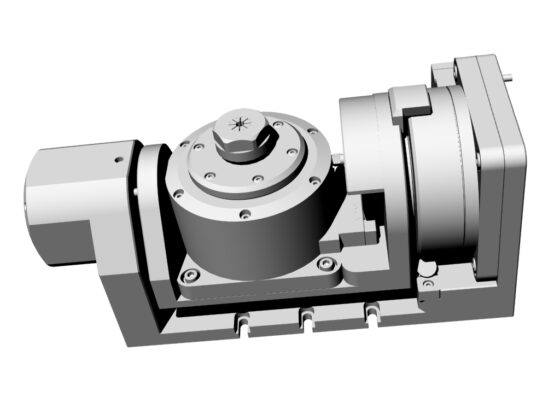

Modular system for controlling different hardware components

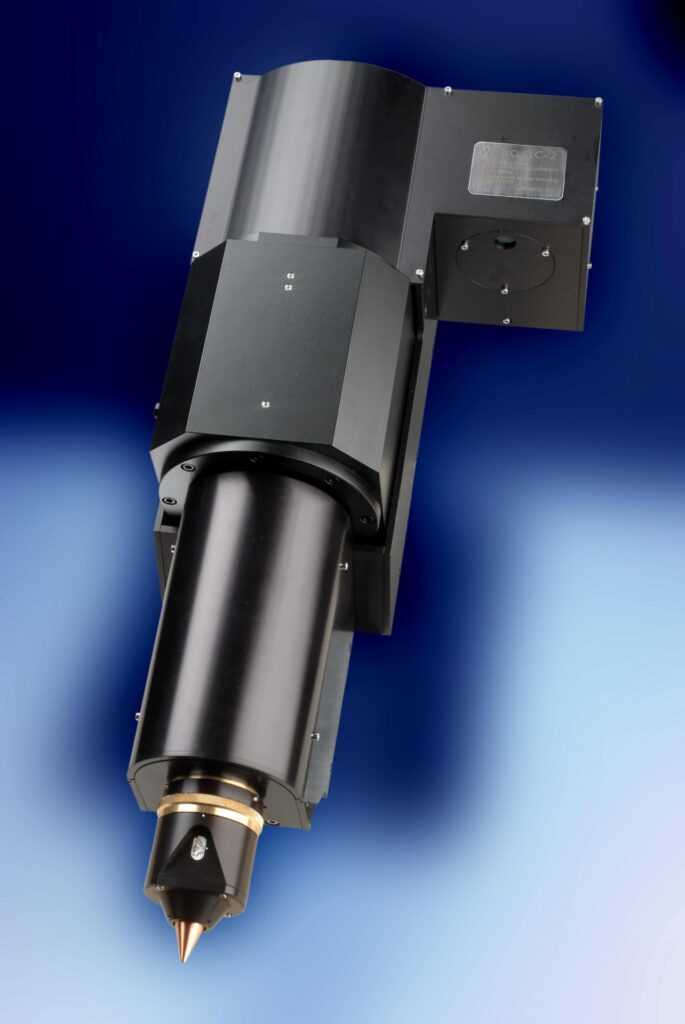

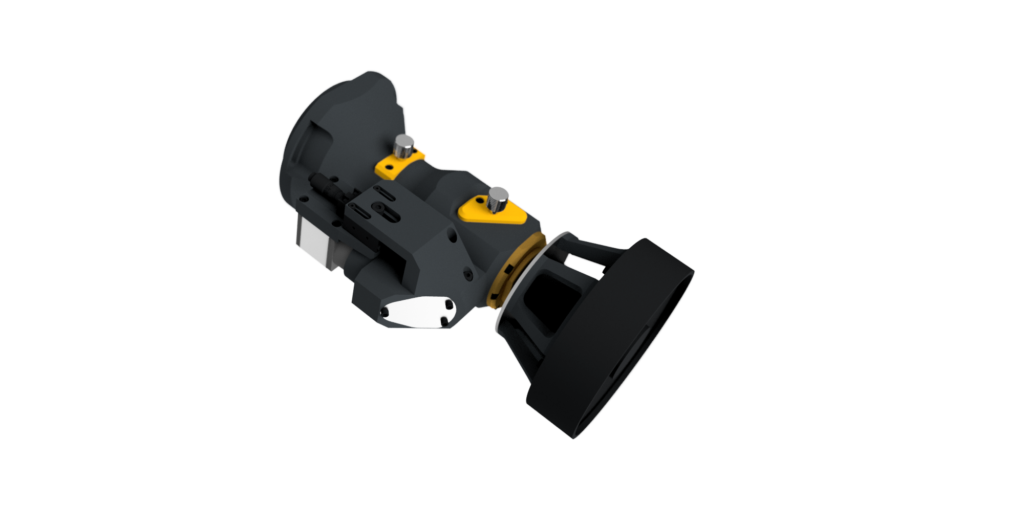

Control panel

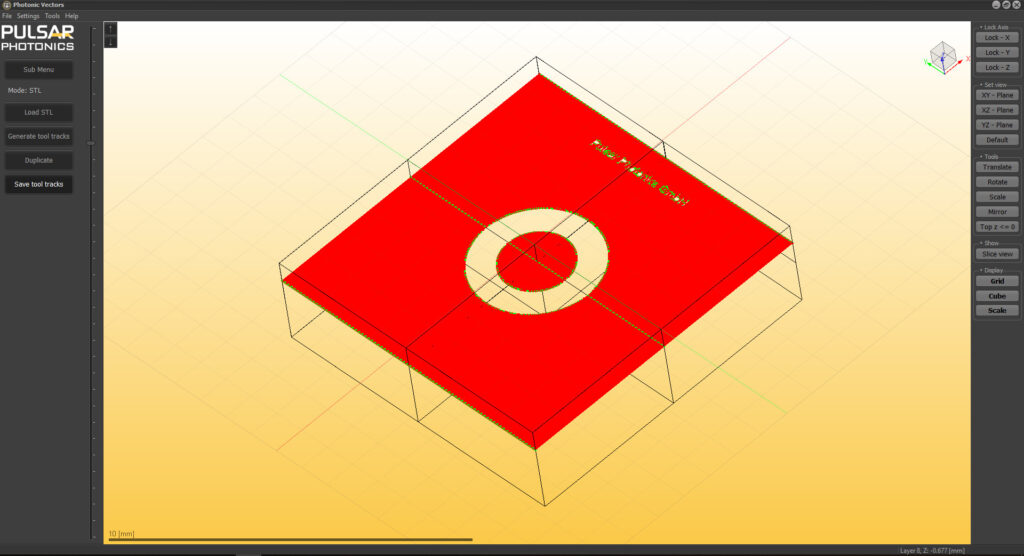

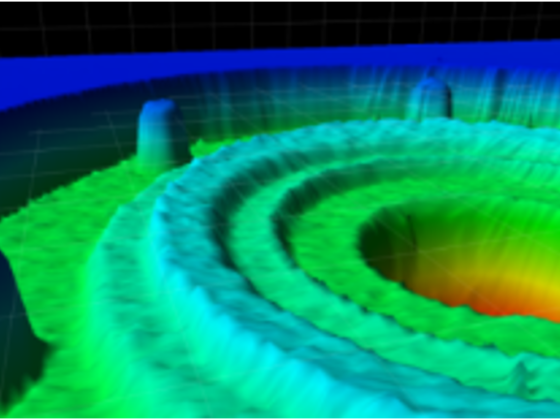

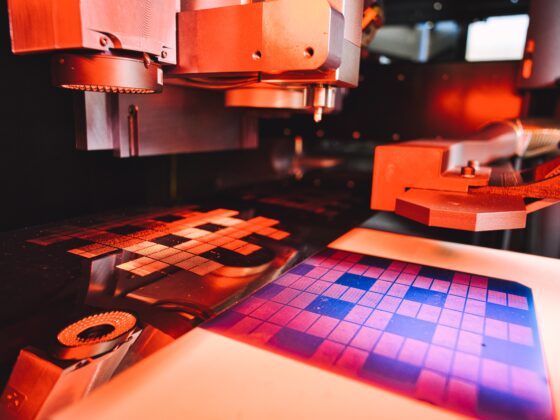

CAM SOFTWARE Photonic vectors

Pulsar Photonics uses its own high-performance CAM solution to prepare machine and vector data (CAM data) for 2.5D laser processing PhotonicVectors . The software with a graphical user interface allows volume models to be loaded, which can then be broken down into layers, scan vectors and axis infeeds in line with the process. As a result, the user receives a finished job file that can be loaded directly into the PhotonicElements machine software and executed there. In addition to a large number of basic settings for 2.5D laser structuring, the following functions are suitable for your application:

- Slicing: Decomposition of the volume model into individual layers. Input of the number of layers into which an ablation volume is to be divided in the z-direction

- Hatching: Hatching of each layer with scan vectors. Enter the hatching with which a layer is to be filled; including hatching spacing, direction, randomization, etc.

- Contouring: Edge cuts with parallel offset to the outer contour. Input of the edge cut parameters with which the outer contour is to be worked out; including distance, number and position

- Tiling / stitching: Automatic division of the target geometry into processing fields of variable sizes. Randomization of the processing fields for quality optimization in multi-layer processing.

- Intelligent tracking: automatic (re) sorting of scan vectors to reduce jump times.

CAD-CAM software for generating scan vectors from CAD data

Import of grayscale bitmap data and decomposition into a 3D volume model

Loading of GerberX data for the production of printed circuit boards, decomposition of the data into scan vectors, creation of a job file

Your personal contact

Benjamin Ipp

Head of Software Development