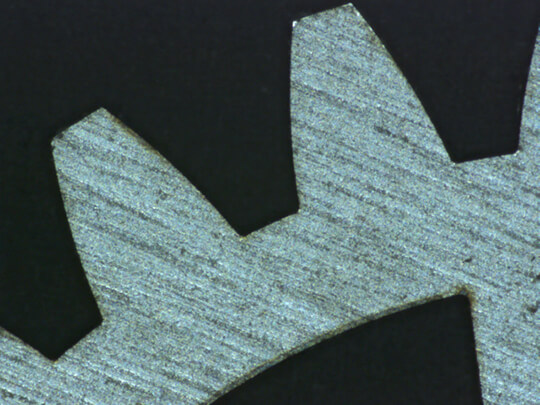

Melt-free laser fine cutting without material distortion

Contour accuracy:

+/- 5 μm, Ra-Werte: < 5 μm

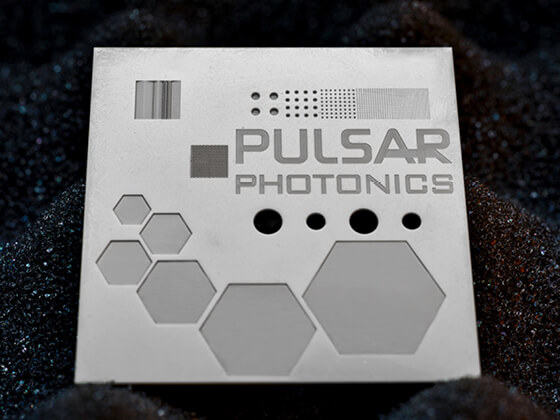

Shape-free cutting of ceramics

Fine laser cutting with the highest edge quality

With the ultra-short pulse laser, flat materials can be cut precisely and with high edge quality

Classic laser cutting has been a well-established process for many years, which is characterized by high cutting speeds with maximum geometric freedom of the cutting contour. However, a large number of materials cannot be processed in this way.

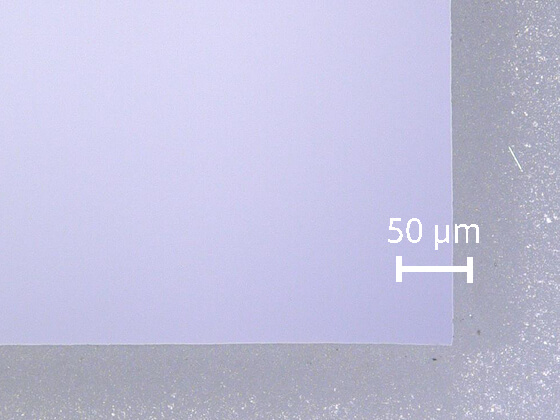

When fine-cutting with (ultra) short pulsed laser radiation the cut is created by removing material in layers without thermal influence on the edge areas. In this way, cuts can also be made in hard, brittle and temperature-sensitive materials or in thin foils. Very high cut qualities with vertical cut edges without melted edges and low roughness values can be achieved.

Fine laser cutting: OUR STATISTICS

Taper angle

Total cutting length on

one component

Smallest web width

of a lattice structure

Fine laser cutting of ceramics and semiconductor materials

High geometry freedom thanks to scanner-based

finecutting .

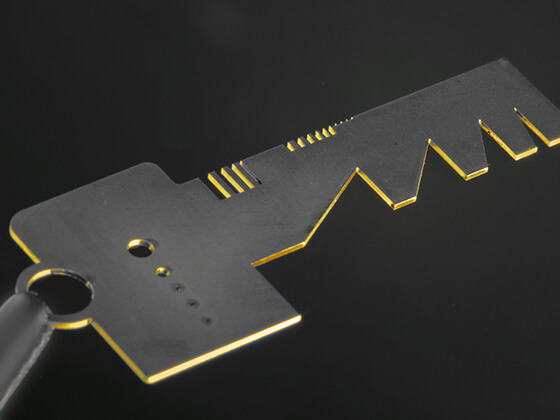

With the classic laser dicing of thin ceramic substrates and semiconductor wafers are mostly used wafer saws or laser-based fixed optics systems. Both processes allow either straight cutting or cutting with comparably large edge radii.

Das scannerbasierte Feinschneiden mit dem Ultrakurzpulslaser erlaubt ein Laserfeinschneiden mit hoher Präzision, kleinen Kantenradien und ohne Mikrorisse im Werkstück. Somit können auch kleine Bohrungen oder Mikroaperturen eingebracht werden.

Achievable qualities

- Ablative laser fine cutting of ceramics and semiconductor materials in free geometries

- Material thicknesses : Typ. < 700 µm

- Edge radius: to < 10 μm

- Aspect ratio Cutting gap width to material thickness; Typ. up to 1:5

- Wall bracket angle: Typ. < 10 °, Helical cutting < 1 °

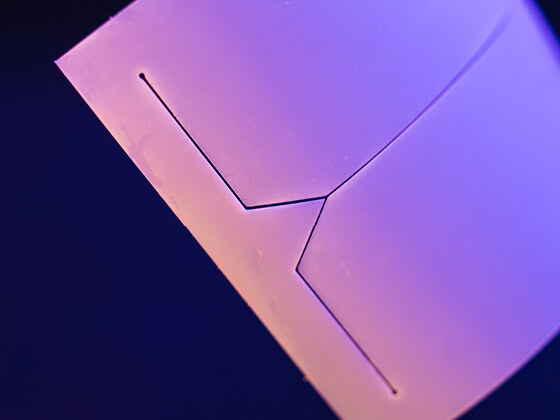

Helical cutting: Precision cuts with vertical cutting edges

Burr-free precision cuts of the highest quality.

Special cutting qualities can be achieved through the Use of special optics getting produced. The cutting edges are absolutely vertical and have a minimum Ra value. Material areas next to the cut edge suffer no heat input and therefore do not change their chemical properties. These cuts are of the highest quality possible in all materials , also in ceramics, (sapphire) glasses, or other brittle materials.

Achievable qualities

- Ablative laser fine cutting of ceramics and semiconductor materials in free geometries

- Material thicknesses : Typ. < 700 µm

- Edge radius: to < 10 μm

- Aspect ratio Cutting gap width to material thickness; Typ. up to 1:5

- Wall bracket angle: Typ. < 10 °, Helical cutting < 1 °

All you need to know about fine laser cutting

Learn more about laser micro processing

for industrial applications.

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales