Modular solution for the

Parallelization of laser processes

Ideal for scaling up of the production of periodic structures or for parallel processing of the same components

Reduction of the processing costs through higher efficient use of the available laser power

Reduction of production costs through massive process parallelization

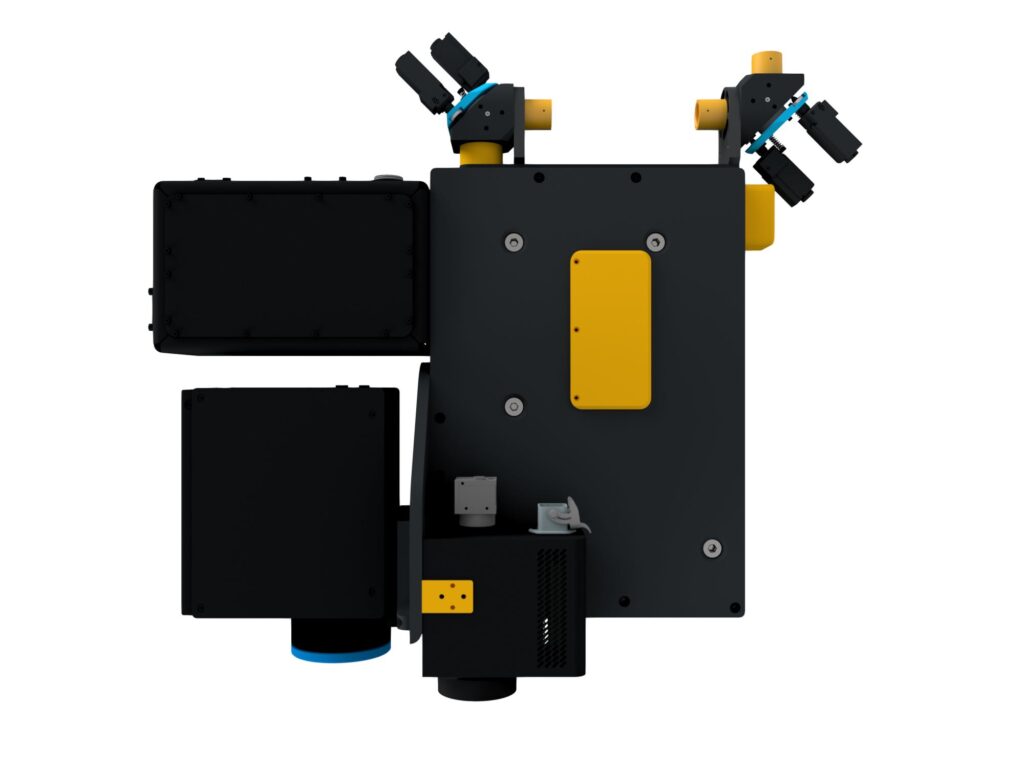

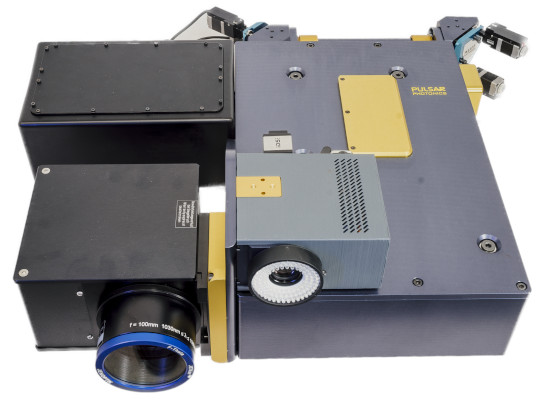

With the MultiBeamScanner (MBS), Pulsar Photonics is for the first time offering a solution for multi-beam processing with a galvo scanner as a commercial product. A fixed beam arrangement is generated in the processing plane of the scanning system. The number of beams and their arrangement can be tailored for the application. This approach allows the process speed to be multiplied when producing periodic repetitive structures. Based on a diffractive beam splitter, the power of the laser system can be divided into up to 100 partial beams and more. This makes it possible to overcome the performance limitations of many USP processes and thus to increase the process efficiency considerably. Areas of application are in the area of laser drilling, the parallel processing of several components or the general parallelization of laser processes.

How the MultiBeamScanner works:

The functionality of the MultiBeamScanner is based on the division of a laser beam by a diffractive beam splitter. Almost any arrangement can be created with this optical element, which convinces with its high level of homogeneity and overall efficiency. In combination with a galvanometer scanner, a large number of processing points can be generated in the processing plane, which are moved simultaneously over the workpiece by the scanner. This allows an efficient parallel production of identical structures in one step.

TECHNIcal DATA

MultiBeam scanner in the application

- Manufacture of periodic structures with the highest precision

- Drilling with extremely high throughputs of more than 14kHz

- Production of coating masks and etching masks

- Large-scale production of microfilters

- Tailored properties for highly stressed parts

- Friction minimization and localized lubrication

- Targeted change in adhesion and wettability

- by introducing microstructures

- Light guide structures for lighting applications

- More efficient use of the available laser power

- Multiplication of the process speed

- Massive parallelization of production

- Reduction of processing costs

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales