Processing of different materials such as Al 2 O 3 ,ZrO 2 , TiO 2 ,SiC and B 4th C.

Laser cutting, laser drilling & laser structuring

Complex geometries with minimal thermal input into the material

Laser processing of technical ceramics

Technical ceramics, such as Silicon nitride (Si 3 N 4th ), Alumina (Al 2 O 3 ), Zirconia (ZrO 2 ), Titanium dioxide (TiO 2 ) are becoming more and more important due to their physicochemical properties and opening up more and more areas of application.

In many applications they are used successfully because of their special heat resistance, strong electrical insulation, physiological compatibility or because of their extreme hardness.

The advantages of the mechanical and biological-chemical properties of technical ceramics are, however, also disadvantages for the machining process: Due to their extreme hardness, ceramics can hardly be cut mechanically. Chemically, too, contours or drill holes can only be created using concentrated acids.

Conventional laser processing lead to breaking or bursting of the technical ceramics due to the high thermal energy introduced.

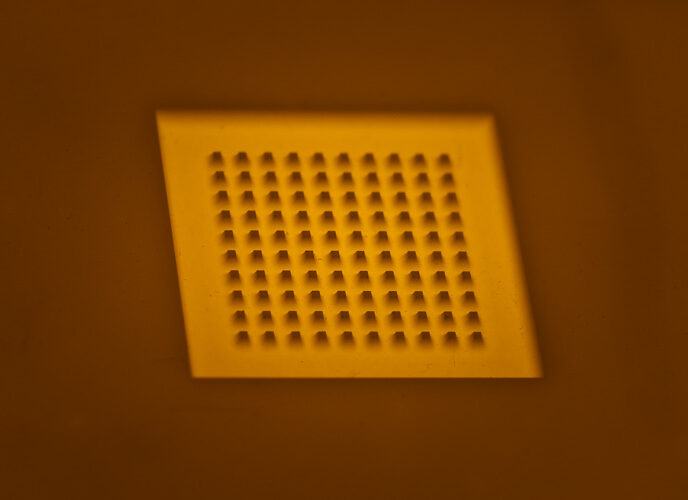

The solution for processing technical ceramics for drilling or ablation provides the use of ultra-short pulse laser technology. The removal and drilling of ceramics with an USP laser is similar to the processing of metals.

Our contract manufacturing for laser drilling, laser cutting und laser structuring mittels UKP-Laser ermöglicht die selektive Bearbeitung von Keramik ohne Mikrorissbildungen.

PULSAR PHOTONICS COVERS THE COMPLETE PROCESS CHAIN

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales