High-precision UKP laser processing of titanium electrodes

Drilling speed of up to 5,000 Hz

Customized drill hole patterns & handling of complex components

Hydrogen electrolysis: Laser drilling of titanium electrodes

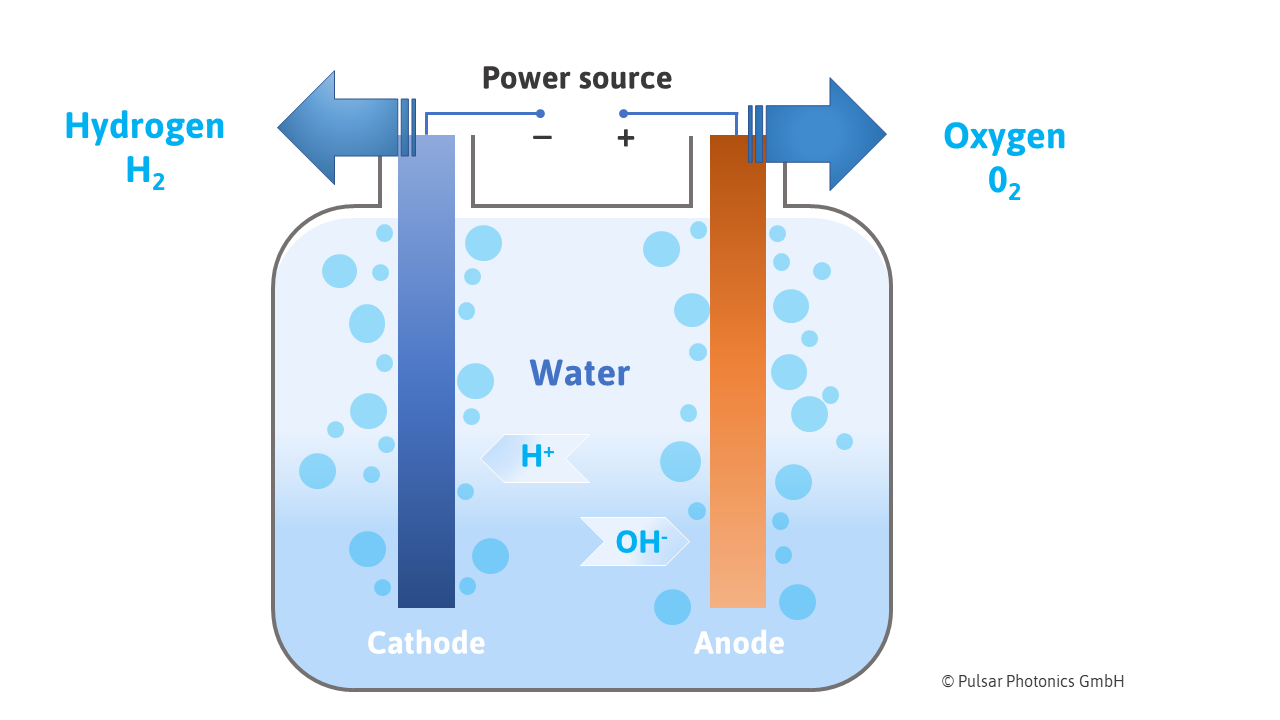

Hydrogen is a key energy source of the future. Electrolysis uses electricity to split water into hydrogen (H₂) and oxygen (O₂). The most important processes are PEM and alkaline electrolysis.

PEM (proton exchange membrane) electrolysis uses an acidic electrolyte that is highly efficient but corrosive. Alkaline electrolysis works with a basic solvent and is more cost-effective. Due to the aggressive conditions, titanium components are often used in PEM systems to increase the durability and lifetime of the components.

Titanium is ideal for laser processing with ultrashort pulse lasers, especially for high-precision drilling, cutting, or structuring processes. Due to their high complexity and technical requirements, the titanium components to be processed are often produced using 3D printing and then further machined using a subsequent laser processing step.

© Pulsar Photonics GmbH.

Functionalization through UKP processing for PEM-Systems

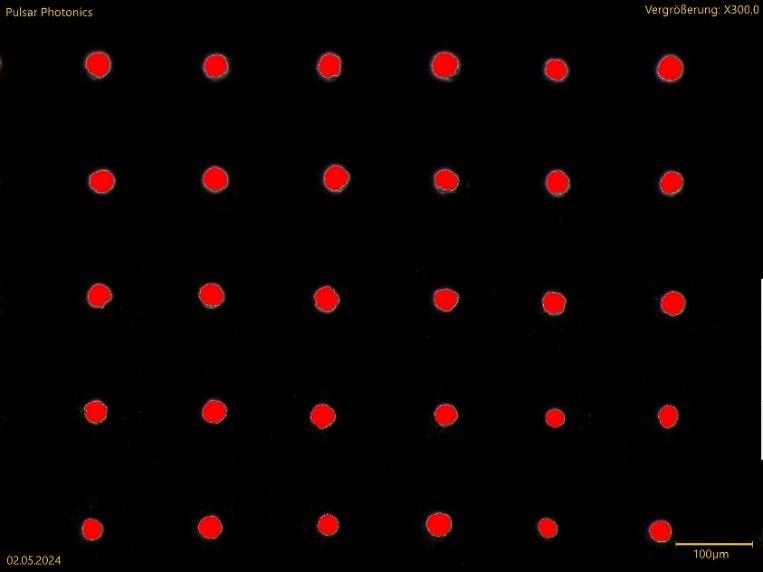

The following technical specifications are possible for laser drilling of electrolyzer plates:

- Drilling speed: up to 5,000 Hz

- Material thickness: 250 µm

- Drill diameter: continuously adjustable, possible in the micrometer range (< 80 µm)

- Drill spacing: 100 – 150 µm

Ultra-short pulse laser processing allows the porosity of titanium electrodes to be customized. The high drilling speeds of up to 5,000 holes per second enable economical manufacturing costs.

Microscope image of a titanium electrode drilled using UKP laser radiation with customized porosity. © Pulsar Photonics GmbH.

PULSAR PHOTONICS covers the complete process chain

Your Personal Contact person

Dennis Pechner

Technical Sales, Laser Application Center