Constant process results through measurement and active correction of the beam position

Modular system adaptable for all machine types and applications

High reliability through correction of pointing errors and thermal drift

Full software integration either as standalone or plugin

active beam alignment for constant process results

When it comes to the accuracy and robustness of processes and machines, beam alignment plays an important role in addition to a reliable laser source and precise optics. When parts are to be processed precisely and with high repeatability, active beam position stabilization can make all the difference.

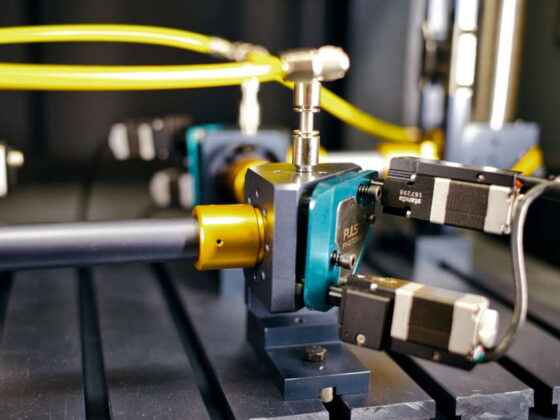

The BAM beam alignment module from Pulsar Photonics is a modular solution for active beam position stabilization. Effects on the beam position due to e.g. pointing errors and thermal effects of laser sources or fluctuations of the ambient temperature can be measured and actively compensated. Thus, constant process results are possible even under fluctuating initial conditions.

The module consists of:

- Beam deflectors developed by Pulsar with mounts for cameras or motorized actuators

- A 2RU 19″ control unit

- BAM software module, compatible with Photonic Elements machine software

Due to its modular design, the BAM can be flexibly adapted to different machine types, designs and applications. Furthermore, the connection of a gas or overpressure purge and the use of the Pulsar Tube System can guarantee a high degree of dust-free operation, making the module suitable for laser sources with high pulse energy and high beam quality.

All beam Parameters At a Glance

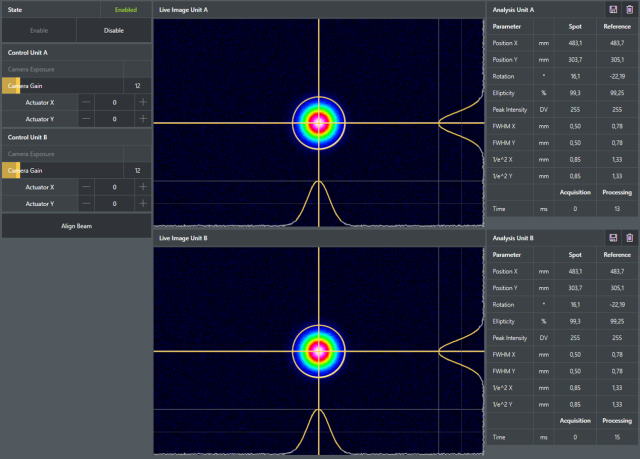

In addition to the right hardware, the right software is also required for optimum control of your beam position.

In the BAM software module, not only can the correction of the beam position be activated and monitored, but the beam position can also be adjusted manually.

Due to the camera-based mode of operation of the BAM, the software determines numerous other beam parameters in addition to the position of the laser beam on the camera:

- FWHM beam diameter

- 1/e² beam diameter

- Ellipticity and rotation

- Beam position

Due to the deep integration of the software module into the Photonic Elements machine software, correction within a process can be automated, enabling consistent results when handling complex and time-consuming processes.

The software module also offers an observation-only mode. Here, beam parameters can be measured over a longer period of time and the data can be stored for later evaluation. Thus, the BAM can also be used for laser diagnostics and for monitoring the aging of a laser source

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales