Highest precision achievable in depth, width

& positioning of the structures

One-time clamping of the shafts increases productivity & processing speed

High degree of automation in production

= high quantities

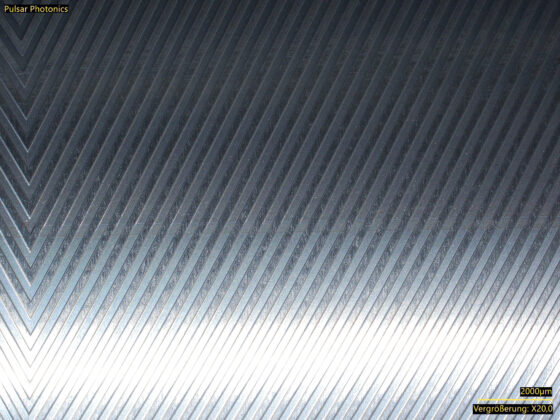

Precision-manufactured shafts with Herringbone gearing using LASER STRUcturing

Shafts with herringbone gearing (double helical gearing) are essential for numerous high-performance applications. Their special geometry ensures high load capacity, low wear and minimal vibrations. By using state-of-the-art ultrashort pulse lasers, these shafts can be manufactured with unprecedented precision and efficiency.

Whether in turbo compressors, X-ray machines or industrial high-performance gearboxes – herringbone shafts are used wherever precise power transmission and low axial loads are required. Their gearing optimizes running and reduces wear to a minimum. High-performance gear shafts in particular benefit from the double helical structure, as they can handle high speeds and high loads with ease.

These shafts can be operated in both lubricated and oil-free applications. They benefit from their low-maintenance and durable design, particularly in sensitive areas such as medical technology or food industry.

Each of these shafts usually requires an axial bearing in order to distribute forces optimally and further optimize operation. These bearings are specially adapted to the respective requirements. Herringbone shafts can be manufactured from a variety of materials, such as stainless steel, titanium, molybdenum, SiC and other high-strength steels and special alloys.

© Pulsar Photonics GmbH.

High quantities thanks to Automation

Ultra-short pulse lasers can be used to produce herringbone structures and matching axial bearings with the highest resolution in the single-digit micrometer range. Advantages of this method:

- Non-contact, material-friendly processing

- Highest precision without mechanical wear

- No post-processing necessary

- Efficient production through automation

- Typical structure widths: 25 µm

- Typical structure depths: 20 µm

- Typical angle of the bone structure: ~ 30 degrees

- Achievable roughness in the structure base: < 1 µm

Shafts with herringbone gearing can be manufactured at Pulsar Photonics in a single clamping process – without any manual effort. Axial bearings are produced cost-effectively and efficiently using automated robotic processes. This results in high-performance components with minimal production costs.

Whether chevron shafts, herringbone shafts or shafts for high speeds with herringbone gearing – this technology ensures durable and precisely manufactured components that meet the highest demands.

Your Personal Contact person

Dennis Pechner

Technical Sales, Laser Application Center