How uLTRASHORT PULSE laser systems innovate and Improve the manufacturing of nebulizers in medical technology

Vaporization of medication: How laser drilled screens surpass the boundaries of conventional manufacturing in medical technology

Louisa Draack | 18th of December 2024 ᛫ 15 min

Medical technology is a field which has been steadily rising to importance over the past decades, with crises such as the COVID-19 pandemic showing just how crucial innovative solutions are for our ability to deal with complex and high-stakes problems.

A product which is especially important for patients of respiratory illnesses is the nebulizer. It serves to atomize medication in such a way that liquid medicine can be inhaled as an aerosol which can distribute itself in the lungs.

The following article explains how ultrashort pulse laser systems can be utilized to manufacture nebulizers for medical applications and which advantages this technology carries.

Function of a nebulizer in medical technology

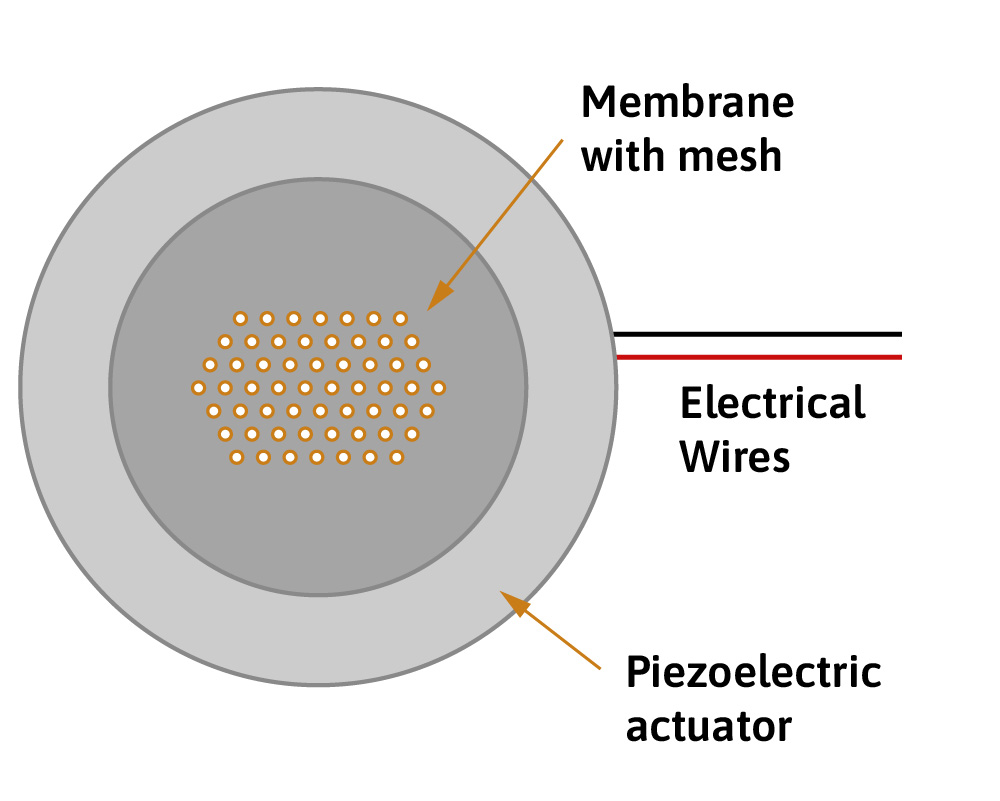

The functional principle of a nebulizer is based on a membrane with micrometer-scale holes. The membrane atomizes medicine by turning them from a liquid into an aerosol. To ensure the resulting aerosol is homogeneous, nebulizers require a continuous actuation. Specially formed piezo discs function as ultrasonic transducers which excite the membrane to perform ultrasonic oscillations in the order of 100 kHz.

Current research shows that smaller sized boreholes lead to the creation of smaller particles of the active agent which can travel further into the lungs achieving higher effectiveness. Thus, the goal should be to miniaturize screen holes as far as possible.

Conventional manufacturing processes reach their limits in this pursuit, as the further reduction of holes becomes either not physically possible or leads to excessively high tool wear. An innovative approach is the use of laser systems with ultrashort pulses, because the shorter the pulses are, the smaller the size of bore hole is which it is able to create. Using the appropriate focusing lens and wavelength of laser radiation, bore hole sizes can be reduced down to a diameter of just five micrometers (5 µm).

Software solutions make adjusting the distribution and shape of bore holes simple, which means one laser processing unit can be used to manufacture an entire range of different products.

The laser drilling process and its influencing factors

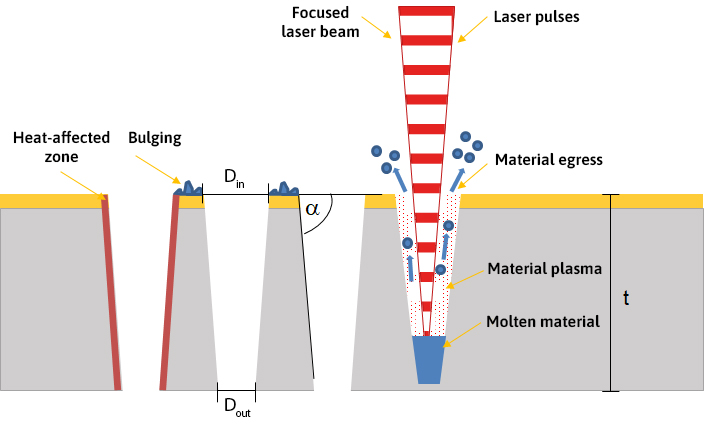

Laser drilling describes a targeted removal of material in a predefined workpiece. In classical high-precision laser drilling an ultrashort pulse laser source is utilized in combination with a beam guidance (and shaping) module, a galvanometer scanner with two scanning mirrors and a focusing module in order to create and control the laser beam. Each individual laser pulse is focused onto the workpiece and absorbed by the material. The absorption leads to a high local heating, and this effect is what removes material from the workpiece. The resulting holes are conical in shape, with the entrance showing a larger diameter than the exit, as seen in the diagram below. The aspect ratio – the ratio between the exit diameter and the hole depth – usually peaks at 1:5.

Several parameters can influence the quality and the cycle time of the process. Lasers with short pulse durations in the order of pico- and femtoseconds do not create melt ejections and bulging and have very small heat-affected zones. This enables a more precise and small-scale processing than is possible with other laser systems with longer pulses.

However, the lower heat input typically means many successive pulses are required to create a hole which usually increases processing time.

To nonetheless enable efficient processing, repetition rates of ultrashort pulse laser systems are typically very high. Percussion drilling, the process whereby material is removed by multiple pulses onto the same area, can reach pulse frequencies of up to 500 MHz – 500 million repetitions per second! But even with this technology, repetition rates can not be scaled without restrictions, as the material vapor created during the process itself absorbs laser radiation which takes energy away from the ablation of underlying material.

The various laser drilling processes explained:

The specifics of laser drilling nebulizer screens

There are several approaches to laser drilling of nebulizers. Which one is most suitable depends on the customers individual requirements. Besides the desired hole diameter, the material thickness, the type of substrate and the specific shape of the borehole are highly influential factors.

As is the case with many products in the field of medical technology, nebulizers are typically made from a stainless steel. These are processable with ultrashort pulse lasers in the infrared, green and ultraviolet spectra. The choice of wavelength is determined by weighing the respective advantages and drawbacks.

While many longer wavelengths such as those in the infrared spectrum generate a larger spot size, they have the advantage of also having a longer Rayleigh length. This metric refers to the length of the waist in the laser beams cross section around its focal distance and indicates the range of focus deviation which has no effect on the quality of the processing result. Even though a smaller laser focus as those of green and ultraviolet wavelengths delivers an even more precise and small-scale processing, its disadvantages, mainly the reduced ablation volume per time, must be taken into account. The fitting wavelength is therefore not only chosen based on the required quality of the end result but must also correspond to the homogeneity of the workpiece material and the required throughput rates.

Often the desired bore hole diameter is below 3 µm because the aforementioned effect of lower droplet sizes is well-known. The thickness of the foil material usually lies around a few tenths of a micrometer, which means that with an aspect ratio of 1:5 the diameter can only be achieved either at the entry or at the exit. All three wavelengths are suitable for the creation of an exit diameter of this size. Because the entrance hole diameter must be significantly higher due to the conicity of the drill hole, a larger amount of material has to be removed which requires a longer processing time.

To counteract this and achieve a further increase in processing rate it is not sufficient to increase the mean laser power of the system. The increased energy density would surpass the ideal point of the material, which would cause it to overheat and deform. To avoid this effect, a so-called burst mode can be utilized. This method divides the laser power into grouped pulses which are individually modulated to control the emitted energy. The mean power remains the same. The burst method allows an increased processing rate and therefore a reduced cycle time.

After an initial parameter study and cycle time optimization, the team in the Pulsar Photonics laser application center was able to use the aforementioned burst method to create 4,000 conical bores with a diameter of 3.5 µm each in a total laser time of 25 seconds. With the resulting membrane, droplet sizes between 4 and 10 µm could be achieved in a nebulizer application.

The result can be seen below: the complete screen is shown on the left, the center is a microscope image of a grid section showing the high uniformity of the result and the picture on the right shows the diameter of an individual bore.

Why Laser machinges are especially suited for the processing of medical parts

Outlook

As there are many possibilities of varying and optimizing both hardware and software parameters, the current results can be further improved upon with more test cycles.

Previously it was shown that droplet sizes around 4 µm are currently achievable. This is however not sufficient for infants and toddlers. Through the use of a specialized laser optic with a very small focus diameter, such as the Pulsar Photonics Microscan Extension (MSE), even smaller boreholes could be achieved, leading to finer aerosol particles.

The testing has shown that a single laser beam can already achieve fast cycle times. Thanks to the flexibility of the laser as a digital tool and the powerful software, laser parameters can still be optimized to increase throughput rates with the single beam.

For industrialized series production processes the cycle time can be reduced by splitting the laser beam up through the use of a scanner module. This method allows for the creation of multiple drill holes with a fixed spacing simultaneously. For example, if the beam is split into four parts, the process can run up to four times faster than with a single beam, because the maximum processing speed per hole is limited by material parameters.

A roll-to-sheet automation process is another powerful tool when increasing throughput rates is the target. The material is placed on coils within the machine and automatically feeds into the laser processing area. After laser processing it can be singled out and automatically handled. This minimizes manual operation and significantly cuts down on idle time.

Do you wish to optimize the manufacturing of your nebulizers? Do you have other microprocessing and drilling needs, which bring mechanical processes to their limits? Contact us, so our experts can conduct initial feasability testing at our laser application center. We are looking forward to hearing from you.

Contact me for an individual consultation in an non-committal initial meeting

About the author:

Louisa Draack, m. Sc.

Louisa Draack is responsible for technical sales at Pulsar Photonics. She has a masters degree in Industrial Engineering from the FH Aachen and nearly six years of experience in the field of laser processing with short and ultrashort pulse lasers.