What are ultrashort pulse lasers?

How ultrashort pulse lasers work, which applications they are found in and which advantages and disadvantages they have

Patrick Gretzki | 27th of May 2024 ᛫ 10 min.

Ultrashort pulse laser – the scalpel of laser technology

The invention of lasers revolutionized many applications and even made entirely new ones possible. Thanks to their high intensity and power density, lasers can be used to cut, texture, modify, weld and ablate many materials. For melting processes such as laser soldering, laser welding and laser cutting, the laser is focussed to a tiny spot and locally melts the material.

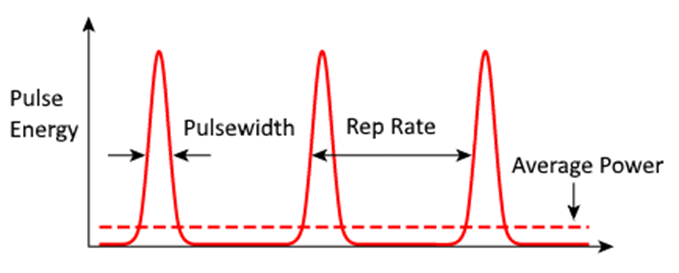

Besides the continuosly operating cw-lasers there is another important category: pulsed laser beam sources. These emit their laser energy in small pulses, the duration of which varies between milliseconds and femtoseconds (0.000 000 000 000 001s) depending on the type of laser utilized. Such laser sources are called short pulse (SP) and ultrashort pulse lasers (USP) respectively. They allow the laser to reach a very high power and intensity at its peak while maintaining a relatively low mean power. A femtosecond laser can reach a momentary output power equivalent to that of a small powerplant (>100 MW) while only drawing a mean power of 10 W, which roughly compares to a small lightbulb.

The physical absorption processes associated with such high intensity radiation can differ greatly compared to longer laser pulses. This means glass, ceramics and polymers can be processed with infrared-USP lasers because they undergo nonlinear absorption processes during the laser-material-interaction.

The following article will show how ultrashort pulse lasers work, which applications they can be found in and which advantages and disadvantages they have.

What constitutes a usp laser?

An ultrashort pulse laser (USP laser) is a type of laser which generates ultra short laser pulses with a duration of a few femto- or picoseconds. The following components play a part:

1. Laser medium

A USP laser typically utilizes a solid laser medium such as a doted crystal or a solid-state laser which is usually combined with an external pulse amplifier. This medium can be made from a variety of materials including glass, crystals such as titanium-sapphire, neodymium- or ytterbium-doted materials. Ytterbium-YAG (Yb:YAG) or neodymium-YAG (Nd:YAG) crystals are most commonly used.

2. MOPA-System

USP lasers for industrial applications require a higher mean power in the range of single- to triple-digit watts. Usually these lasers separate the generation and amplification of pulses into two components. This approach is called MOPA: Master Oscillator Power Amplifier. This means a laser (master oscillator) initially generates the ultrashort pulses with a high frequency (repetition rate) and low pulse energy. Some of these pulses are selected (the repetition rate is typically reduced by an integer factor) and transmitted to a power amplifier. This component increases the pulse energy of the individual pulses.

3. Pulse Generation (Master Oscillator)

The ultrashort laser pulses the principle is based on are generated by a technique called mode coupling. This involves synchronizing the different laser modes (oscillation states) within the laser resonator in such a way that they overlap and create a very short but highly intense laser pulse.

4. Pulse Amplification (Power Amplifier)

The amplification of laser pulses typically occurs in a pulsed laser medium. The amplification of the laser pulse means an increase in its pulse energy. Different amplifier geometries are possible (disc, rod, fiber, slab).

5. Pulse compression

After amplification, the laser pulse can be compressed by special optics in order to further increase or decrease the pulse duration. This is usually achieved through diffraction gratings or special glass fibers.

The resulting pulses have an extremely short duration and a high spectral bandwidth with a correspondent high maximum power. To explain, we shall use the following example of a laser system:

Laser type Yb:YAG, 1030 nm | mean power 20 W | pulse duration 1 ps | frequency 400 kHz

This is a laser based on a Ytterbium-YAG crystal as a laser medium with a wavelength of 1030 nm. The mean power of 20 W and the repetition rate of 400 kHz result in a maximum pulse energy of 50 µJ. The laser pulse has a peak power of 100 MW. If it is focussed onto a spot with a diameter of 35 µm (focal length 100 mm), an intensity of ~10^13 W/cm² is achieved. For comparison: the sun’s intensity is 0,1361 W/cm².

6. Wavelength conversion

Depending on the application area, it may be advantageous to reduce the laser wavelength – for example to increase resolution or absorption. Frequency conversion is a helpful tool for this. The laser pulses are conducted through a medium which creates a so-called higher harmonic when irradiated with an intense laser radiation. The higher harmonic consists of laser radiation with double (SHG) or triple (THG) the input frequency, in other words half or one third of the input wavelength. Frequency conversion creates power losses but allows a simple conversion from IR (1030 nm) to green (515 nm) or UV (343 nm) laser radiation.

ALl the advantages for material processing – A summary:

Material processing with ultrashort pulse lasers

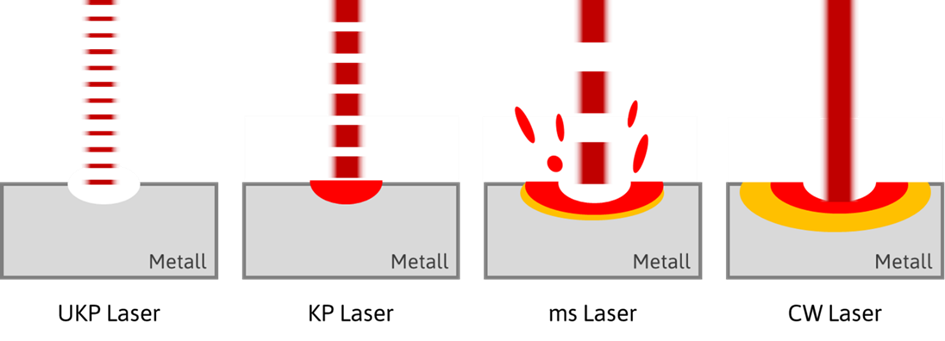

The physical processes involved in the use of USP lasers are fundamentally different from those associated with continuous wave (cw) processing. The radiation of a cw laser is absorbed by the material and converted into heat. The material (most often metals) melts and the surrounding area conducts part of the heat into the rest of the material. This results in a large area being heated and can cause a change in the material’s structure. The affected area is called heat-affected zone (HAZ).

The shorter the pulses become, the higher the resulting local intensity is. The material is heated up faster, which means there is less time for heat to be conducted away. As a result, shorter pulses cause higher maximum temperatures in the material and lead to local vaporization.

If pulse duration is decreased even further, nonlinear effects can start to be seen. Classical absorption effects are no longer applicable. For example: glass is nearly 100 % transparent for green light. A continuous laser beam with a low intensity would barely be absorbed and ultimately have no effect. However, if a critical intensity is exceeded, multi-photon absorption occurs. This means glass is no longer transparent for green light with picosecond-length pulses and can be processed with a USP laser in this range.

In metals, the laser energy is absorbed in a very shallow layer near the surface. USP lasers, due to their high intensity, immediately cause high temperatures far above the evaporation point. The material is not able to transport heat to other areas in such a short time. This leads to a highly localized energy input and causes the evaporated material to be shot out of the ablation zone akin to an explosion. Because the surrounding area doesn’t heat up, the term cold ablation is commonly used to describe this process.

Examples for the use of usp lasers

Thanks to their unique optical properties and interactions with material, USP lasers have a wide range of applications. Their high precision and special abilities have made them an important tool in many industries.

The applications can roughly be categorized as follows:

1. Material processing: USP lasers are utilized for precise material processing applications such as micro processing, fine drilling, engraving, cutting and surface texturing.

2. Medical applications: USP lasers are useful in medical applications such as corrective eye surgery and dermatological therapies.

3. Research and science: USP lasers are deployed in numerous scientific research applications including spectroscopy, microscopy and material characterization.

4. Optical coherence tomography (OCT): USP lasers are used in OCT imaging to create high resolution cross-section images of biological tissue and other materials, which makes them indispensable for medical diagnosis applications.

5. Photovoltaics: USP lasers are used in the solar industry for the precise machining of solar cells and other components to increase their efficiency. Thanks to their high material and depth selectivity they are also useful for the processing of thin films.

6. Nanotechnology: USP lasers are utilized in nanotechnology applications for the manufacturing and characterization of nanostructures, nanoparticles and nanoscale-materials. The particular physical interaction of lasers enables the creation of nanoparticles without the use of any solvents or stabilizers.

An Overview of various application areas of usp lasers at pulsar photonics:

Pros and Cons of laser material processing

USP lasers, with their high intensity and nonlinear absorption characteristics, have the advantage that processing of the material is highly localized. At the point of impact, material can be ablated with a depth resolution of a few hundred nanometers. Thanks to the short timescale of each pulse, there are no thermal effects on the surrounding area. This also enables the processing of layered systems where several materials are combined. Because material is nearly instantly vaporized, melt deposits can be avoided. The high selectivity of USP lasers further allows processing on a microscopic scale, achieving both a high level of precision and structural quality.

The downside of a highly depth-selective processing is that the amount of ablated material per pulse is low in comparison to longer pulse sources. This is because a large portion of the input energy is converted into the vaporization of material and the creation of plasma. In this context, productivity is measured in volume per time unit or volume per watt of power used and for the former usually lies in the scale of mm³/min. The use of laser beam sources with a high mean power and corresponding optical systems can accelerate these laser processes significantly. Typical costs for USP laser beam sources lie in the range of 80.000 – 180.000 € for 20 – 100 W laser power.

To understand, how costs for a laser machine are determined, read our article on the subject.

However, the scaleability of USP laser processes through a simple increase in laser power in single beam machining is limited due to its effect on the product quality. Furthermore, while from a purely technical point of view large surface areas are processable, the manufacturing costs associated with classical single beam processing currently limit the economic viability of USP laser manufactured applications for large surface areas. In order to circumvent these limitations, multi-beam technologies have been developed in recent years. These open up new application areas and potentials for a vast array of industries.

With its optics modules and system technology, Pulsar Photonics offers solutions which enable various scaling methods, especially for USP laser processes. For example, many processes are easily scaleable with multi-beam or multi-scanner solutions.

Summary

Laser processing is revolutionizing the way in which we manufacture products and will have a major impact on the future of manufacturing and machining. Companies which invest in these technologies will be able to raise their competitiveness and keep ahead in a constantly changing global economic environment. Ultrashort pulse (USP) lasers, with their ability to create extremely short laser pulses in the femto- and picosecond range, represent the pinnacle of laser technology. With innovative scaling methods they are able to process surface areas up to the square meter range.

USP lasers can raise the precision of laser processing even further and enable the processing of challenging materials. These properties make them an indispensable tool in many high-tech industries and research areas. With new processes and machines, part costs can be lowered to a competitive level, helping the technology to further penetrate the market.

Do you have questions concerning USP lasers or scaling approaches?

on the author:

Patrick Gretzki

Patrick Gretzki is head of system technology at Pulsar Photonics. After studying physics at the RWTH, he worked in USP laser material processing for 8 years at Fraunhofer ILT where he, among other things, lead the team for thin film processing.

More information about system technology at Pulsar Photonics can be found here.