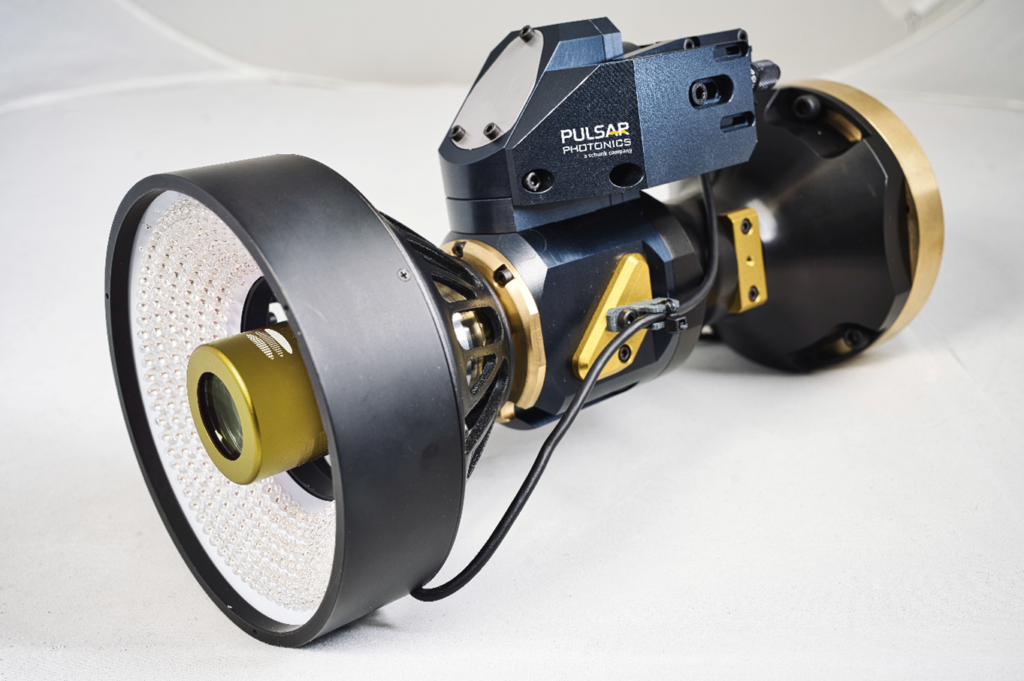

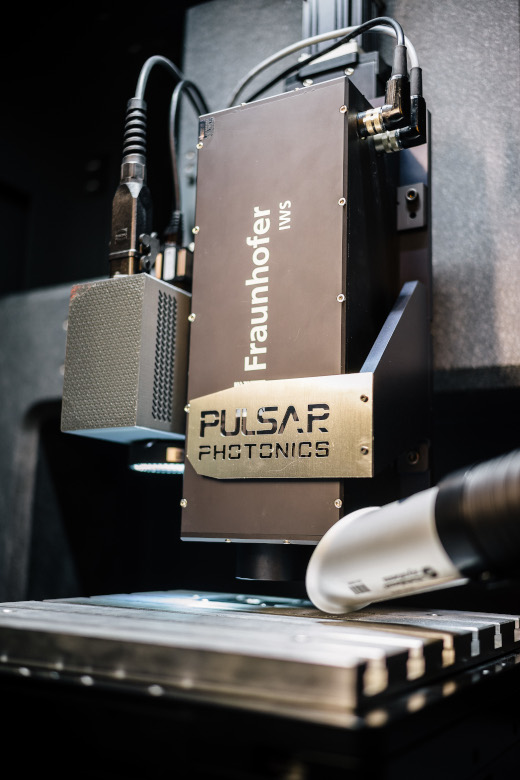

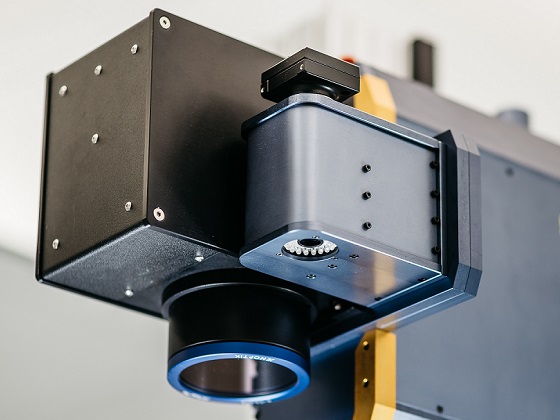

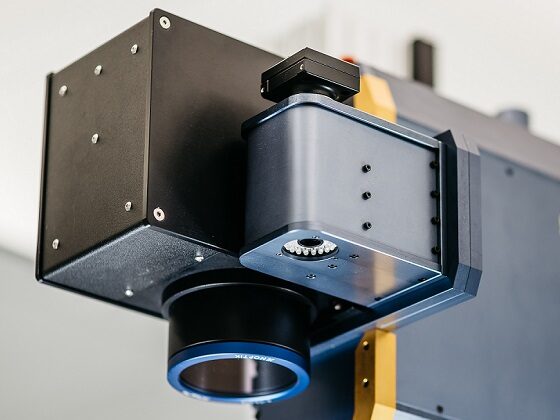

Herzogenrath (Germany), 25 Jan. 2022: Pulsar Photonics GmbH, laser technology specialist from Herzogenrath, presents the Microscan extension, a scanning lens for laser micromachining that achieves resolutions close to the sub-micrometer limit and can turn any galvanometer scanning system into a microscanning system in just a few minutes.

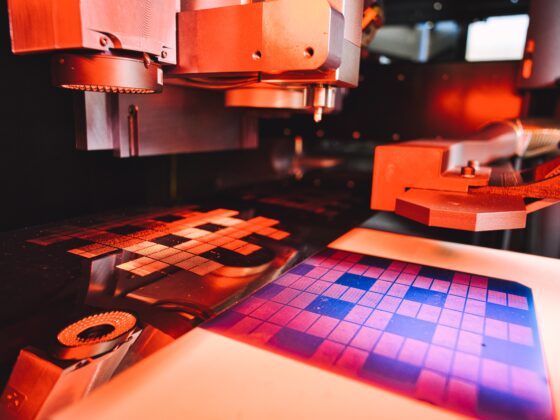

With the help of the UV version of the Microscan extension, a galvanometer scanner and a UKP laser, structure sizes in the single-digit micrometer range can be realised by laser ablation, opening up completely new areas of application, especially in the fields of medical technology, microfiltration and electronics.

Ongoing miniaturisation of components

The miniaturisation of components is no longer only relevant in electronics. This development is also gaining importance in areas such as medical or process engineering. In medicine, for example, microcatheters are being used more and more frequently, which can deliver active substances in a targeted manner with the aid of precise microbores. In process engineering, microsieves with output diameters in the single-digit micrometer range enable targeted flow control.

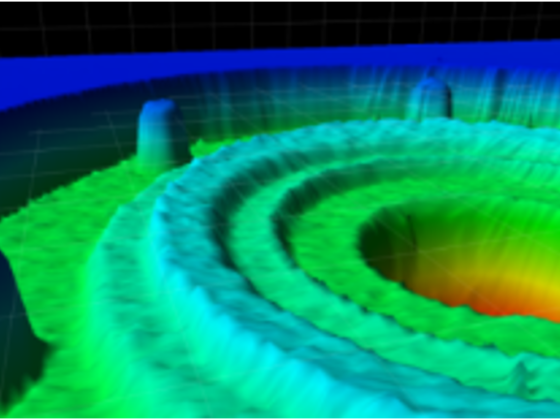

Reproducible microdrilling, micromarking or ablation with high structural resolution down to the sub-micrometer range require suitable manufacturing processes. Until now, UKP lasers have only been able to ablate structures in the 10-500µm size range, mainly due to the available scanning technology as well as focusing.

Can be used in a few minutes

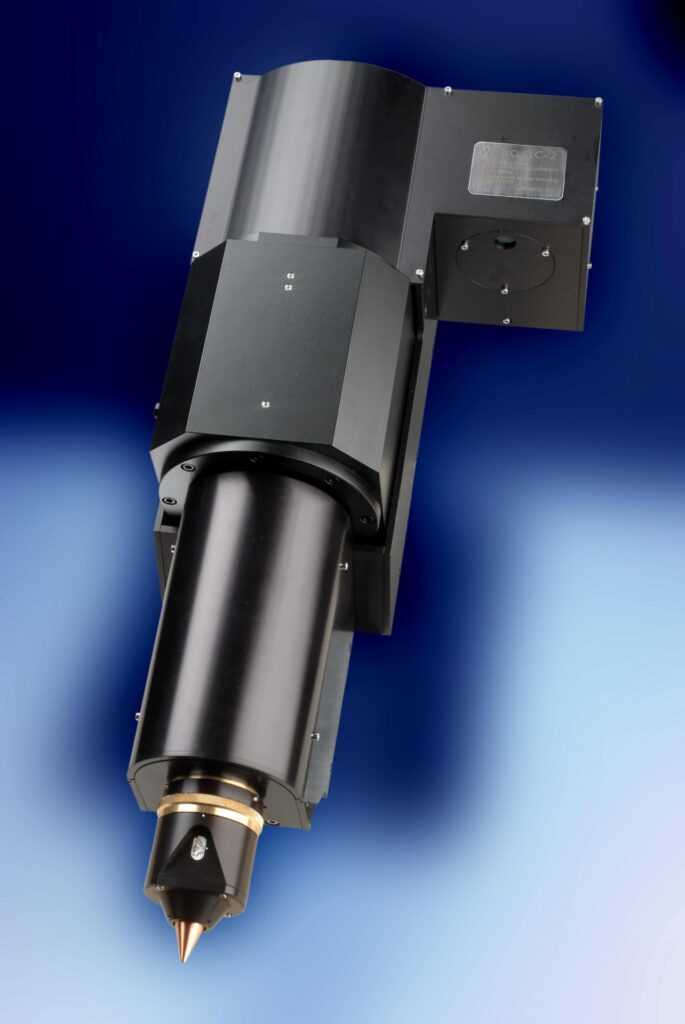

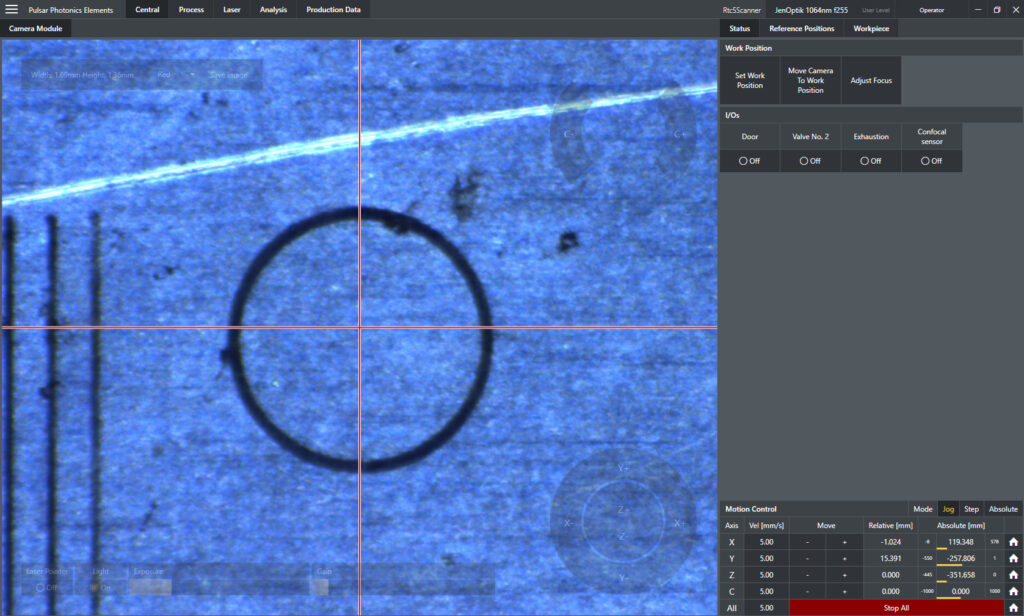

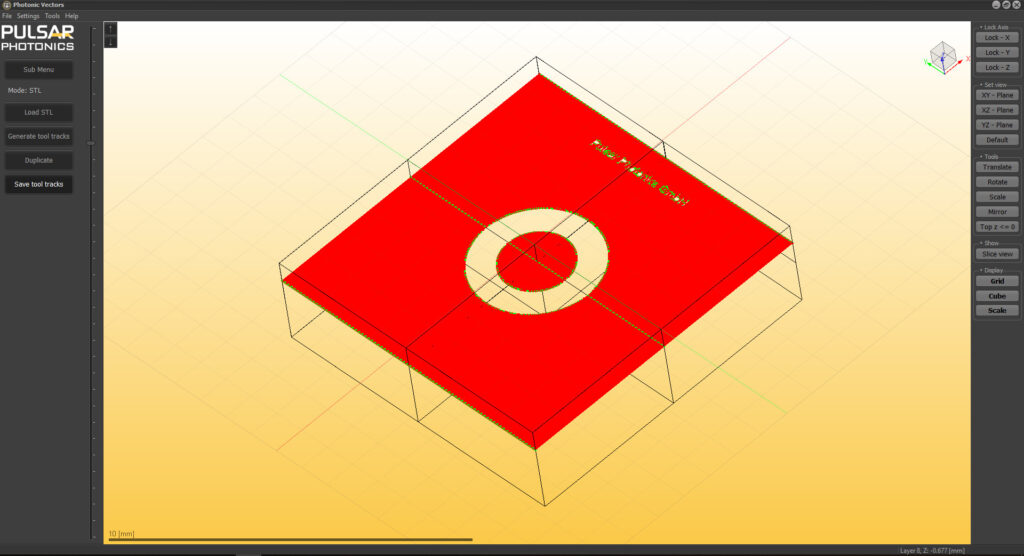

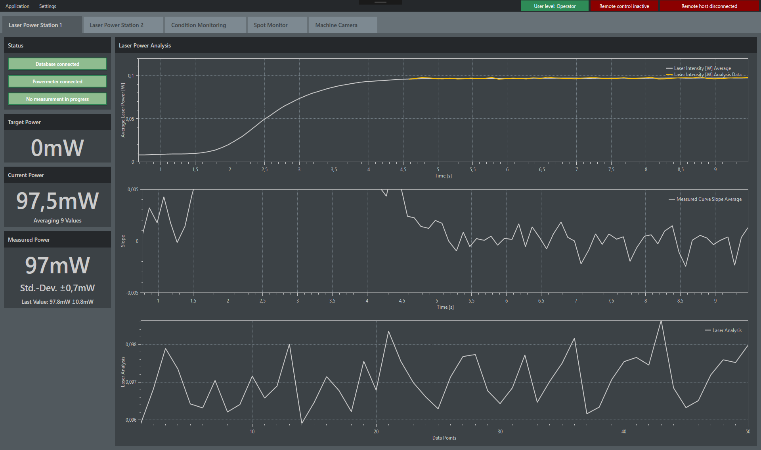

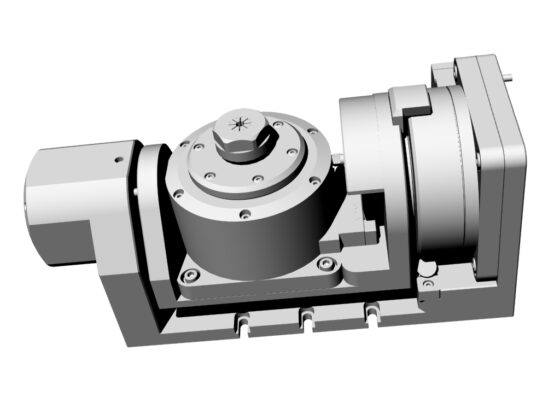

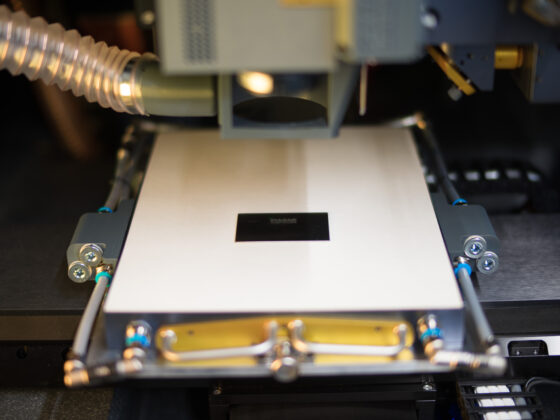

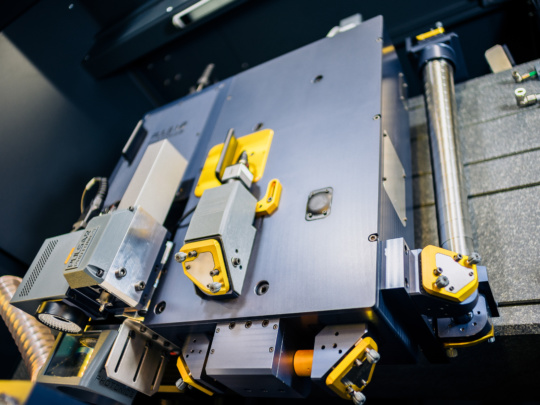

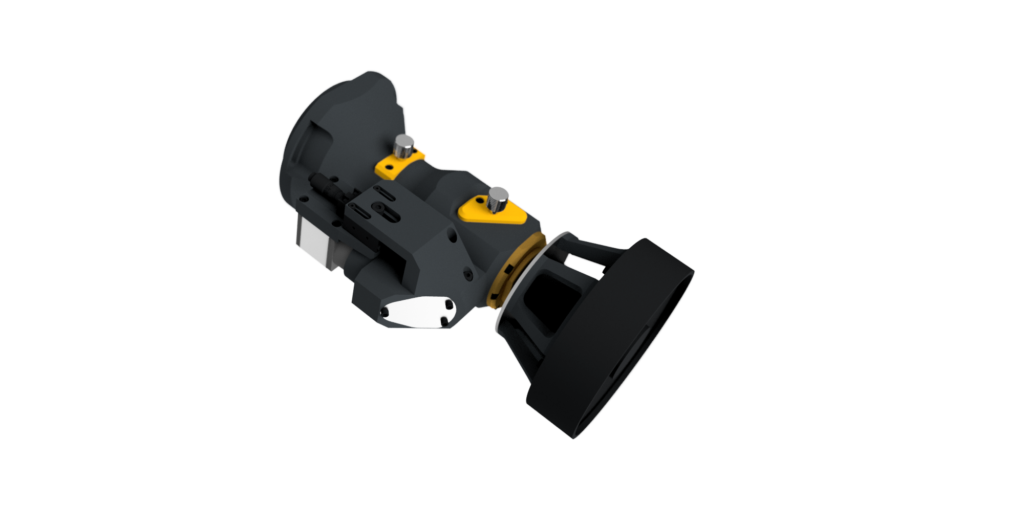

The Microscan extension from Pulsar Photonics is capable of producing structure sizes in the range of less than <10µm. It can be mounted on a galvanometer scanner like a conventional F-theta lens, making a UKP laser machine ready for high-resolution micromachining in a few minutes. Using the newly developed UV version of the Microscan extension, even focus diameters of up to 1.3µm (1/e²) can be realised on the workpiece. Modern galvanometer scanners with digital encoders enable the micrometer tool to be guided over the workpiece with an accuracy of <100nm. The calibration of the sample as well as the adjustment of the focus position are carried out via the coaxial camera of the scan lens.

Dr. Stephan Eifel, Managing Director at Pulsar Photonics GmbH:

“Our new Microscan technology is our answer to the individual requirements of the market. It enables laser drilling of initial diameters of less than 1.5µm in thin steel foils or microcatheters in a reproducible manner. At the same time, the Microscan extension can introduce micro-markings with high information density on flat surfaces in a process-safe and highly individualisable way, thus extending the application range of UKP lasers to the sub-micrometer limit.”

Pulsar Photonics

Pulsar Photonics GmbH is an innovative high-tech company in the field of laser technology. Its range of services includes the development, production and distribution of laser machines for material processing with short and ultra-short pulse lasers. A second core competence of the company is the integration of tooling and measuring systems for material processing, adapted to the specific requirements of the application. Besides its expertise in system development, Pulsar Photonics is also a competent partner for single-part and series production with (ultra-)short pulse lasers. Its core processes focus on structuring, drilling and precision cutting. Founded in 2013, Pulsar Photonics GmbH is one of the fastest growing companies in Europe, according to the Financial Times and Statista. Pulsar Photonics has been part of the Schunk Group since 2021.

Contact

Pulsar Photonics GmbH

Dr. Stephan Eifel

presse@pulsar-photonics.de

www.pulsar-photonics.de